Find the right camera for vision systems in the food and beverage industry

Every vision system in food & beverages has its individual requirements. We know how to help you find the best camera solution for your application.

As the global population steadily grows and the demand for food rises, the quest for secure supply chains becomes paramount. Navigating the complex landscape of food safety and quality challenges, our state-of-the-art cameras emerge as indispensable partners, ensuring not only the uniformity of food quality but also driving production efficiency to unprecedented levels.

Vision systems play a transformative role in inspecting food from measuring geometrics, analysing the quality, detecting foreign objects, and scrutinizing packaging. Our cameras support sorting and grading processes, barcode reading, label inspections, and robotics.

Also, quality assurance in the beverage industry requires cameras for bottle cap and sidewall inspection, fill level, and cracks or material defects detection.

The stakes are high – even minor disruptions can lead to massive losses. Our cameras stand as guardians of uninterrupted operations, seamlessly adapting to diverse setups, ensuring every frame in your production story is one of efficiency and perfection.

Application-specific camera requirements

Allied Vision cameras support these requirements with a wide range of reliable technologies, platforms, and features:

- Solid and easy addressable interfaces like 1GigE/5GigE allow multi-camera setups and long cable lengths on factory floor level

- Ability to customize with bandpass filters to improve image contrast

- Optional IP67 housings, and variable mounting/connecting opportunities to withstand rough environments

- Features like "region of interest" to increase the speed to very high frames per second

- Advanced trigger and sequencer functions to ensure precise synchronization of processes

- Global shutter technology to avoid blur effects

- OEM / Customized services up to highest complexity

Our cameras for color and SWIR imaging

Alvium G1 – versatility meets unmatched image quality

Our Alvium combines the advantages of the established GigE Vision standard with the flexibility of the Alvium platform. Equipped with a Color Correction Matrix to ensure accurate color representation even under challenging lighting conditions and a comprehensive Multi-ROI implementation for efficient and targeted inspection, our Alvium G1 camera boasts a well-suited feature set for vision systems in the food and beverage industry. Featuring over 17 global shutter sensors from 0.3 MP up to 24.6 MP, including hyperspectral options (UV, NIR & SWIR), Alvium G1 stands out as a versatile solution for a wide range of applications in the food and beverages industry. With a best-in-class temperature range of -20°C to 65°C, it ensures optimal image quality even in changing conditions.

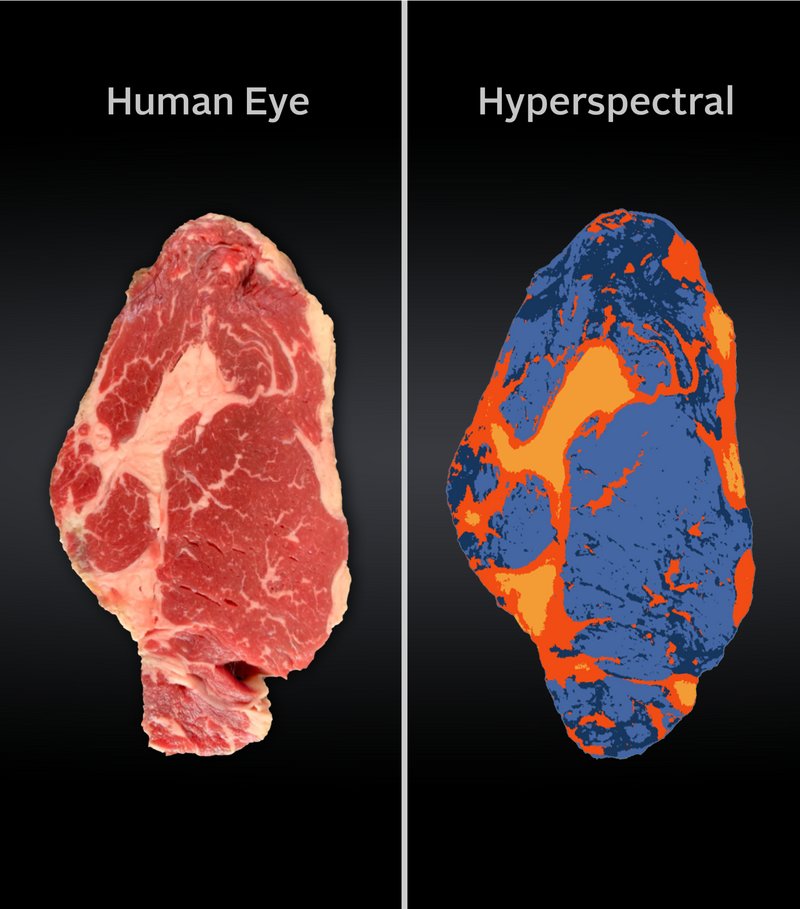

Contrasting lean and fat: beef steak in visible versus hyperspectral imaging; Image source right side: Clyde HSI

Infrared Imaging – see beyond the visible

Near-infrared (NIR) and short-wave infrared (SWIR) cameras can further improve the quality of inspection systems. We offer our Alvium SWIR camera series with so-called SWaP+C functionality – Innovative SWIR technology in a compact design at an affordable price. For higher demands on image quality and reproducibility, our Goldeye SWIR camera series with thermo-electric cooling (TEC) are available, which support a variety of InGaAs sensors with high dynamic range and low noise. Both cameras offer high linearity and excellent image homogeneity, supported by the sensor itself (models with IMX99x) and/or an automatic 2-point correction (Goldeye models). In addition, the cameras have a flexible multiple selection of ROIs. The cameras are easy to set up and therefore ensure a real plug & play experience.

Finding the right camera for your application

For more than 30 years, Allied Vision has been helping people to reach their imaging goals. By focusing on what counts for each customer, Allied Vision finds solutions for every application, a practice which has made Allied Vision one of the leading camera manufacturers worldwide in the machine vision market.

Our engineers design digital cameras with a large scope of resolutions, frame rates, bandwidths, interfaces, spectral sensitivities, sensor technologies, and technical platforms.