Vision Solutions for Warehouse Automation

Transform your Warehouse with Allied Vision: Cutting-edge Vision Solutions

Your Challenges: Machine Vision in Warehouse Automation

Environmental Conditions

Changing light intensity with vibrations or movement causing blurry images.

Data Quality

The difficulties in collecting high-quality data in a warehouse setting, to ensure they are accurate, consistent, and representative of the warehouse environment.

Real-time processing

Computer vision systems in warehouses often require real-time processing to keep up with the fast-paced environment.

Our Solution: Overcoming Environmental and Data Challenges

High image contrast

with features like sequencer to acquire images of an object in up to 16 different settings (e.g. exposuretime, framerate, balance ratio, gamma, saturation)

High-Quality Camera Sensors

that can capture high-resolution images with good low-light sensitivity, which can improve data quality and reduce the need for manual annotation.

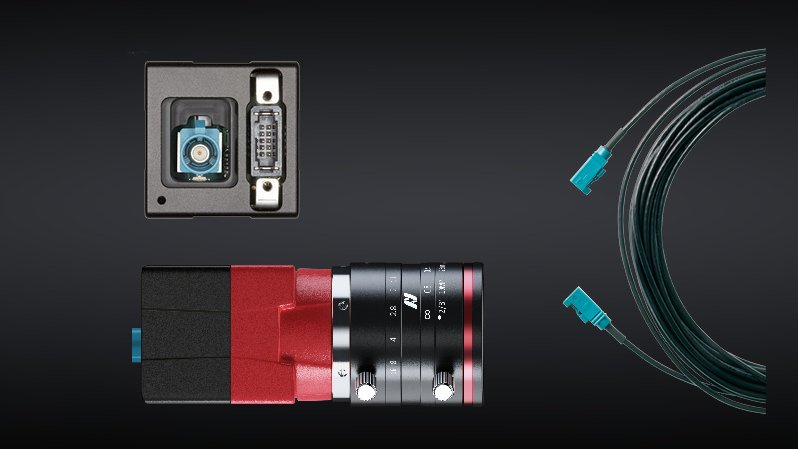

Camera Interfaces & Low-Latency

GigE, USB3, FPD-Link III and GMSL2 enable fast data transfer with GenICam standard. Low-latency protocols like CSI-2 to reduce communication overhead and enable faster data transfer.

Applications in Warehouse Automation

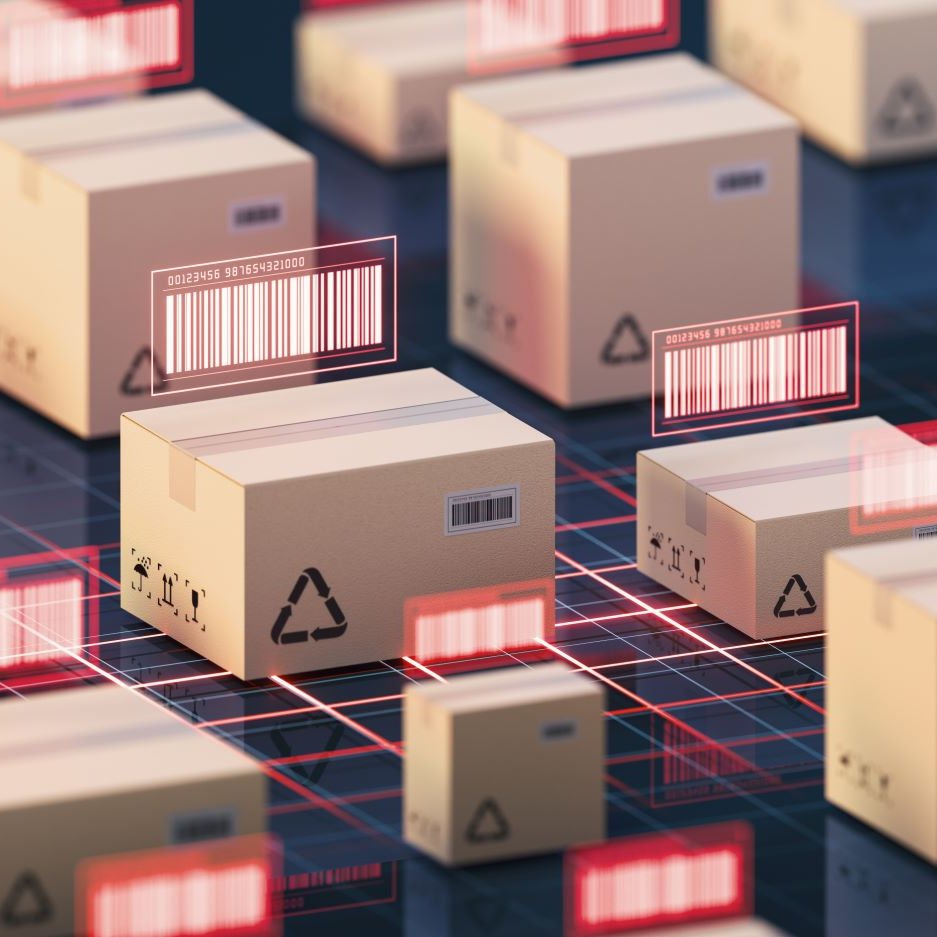

Barcode & QR reading

Shape detection

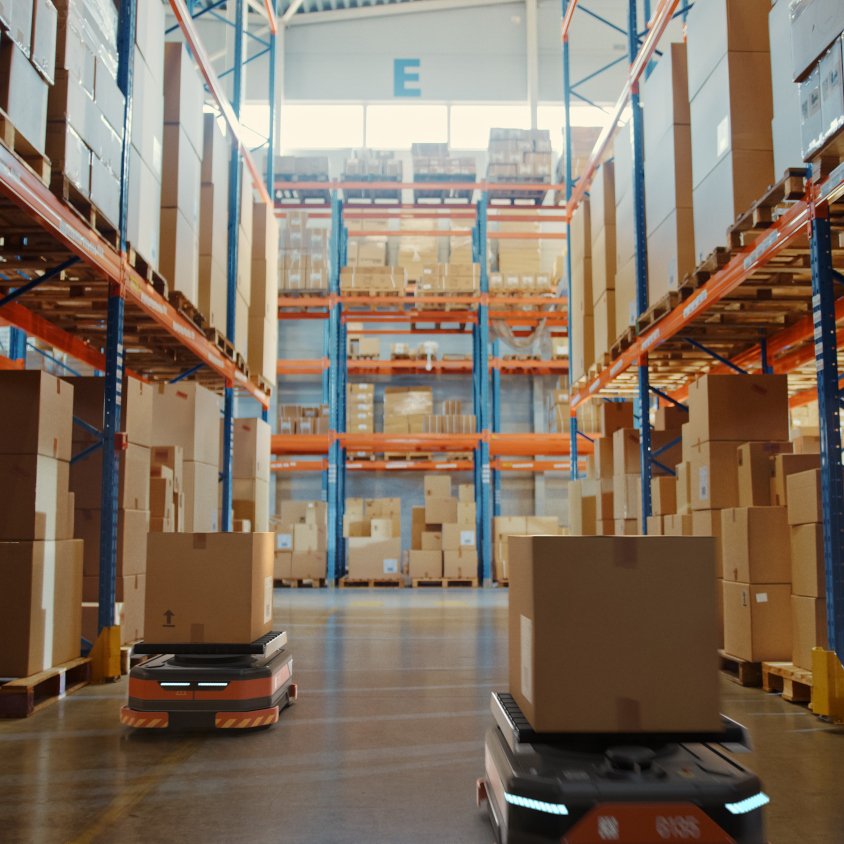

Inventory control in warehouses

Position detection

Mail and parcel sorting

Object classification and counting

Warehouse surveillance

Collision avoidance for AGVs and forklifts

Why choose Allied Vision Cameras for Logistics and Warehouse Automation Applications?

When choosing a Camera for Warehouse Automation, the following Aspects are relevant:

- High frames per second for high speed applications on conveyer belts

- Low latency and low system overhead for safety and real time relevant applications

- A sensor portfolio that fulfils your needs for your application from 0,3 to 25 MP

- Long cables for multi-camera solutions or greater distance between camera and host

- High data throughput with GigE Vision or CSI-2 for embedded boards and systems

- High resolution for small barcodes in a larger field of view (FOV)

- Small size for space constrains and weight limitations on vehicles with sugar cube or bareboard design

- Faster go to market for full featured open source drivers with MIPI CSI-2, FPD-Link III and GMSL2

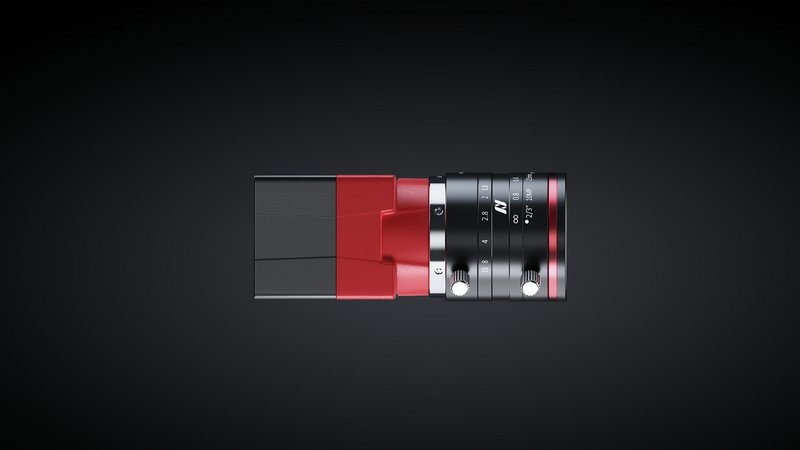

The Alvium G1 & G5 is the perfect choice for warehouse automation applications. With its high image quality and flexibility, it can accurately capture colors and details even in challenging lighting conditions. Whether for conveyors or on robotic arms, the GigE interface cameras delivers reliable results for efficient quality control.

Alvium FP3 cameras with FPD-Link III interface and Alvium GM2 Coax cameras with GMSL2™ have been designed to overcome the limitations of standard CSI-2 cameras. There are more than 30 high-quality image sensors to choose from and is a perfect long cable solution for logistics and warehouse automation.

Interested in a reliable longterm partnership with Allied Vision & TKH Vision?

With over 30 years of experience, Allied Vision stands at the forefront of machine vision technology, harnessing the power of German engineering. As a key player within TKH Vision, a collaborative force of specialized brands, we're backed by solid resources and a shared dedication to excellence, ensuring reliable and high-quality solutions for demanding defense applications.

Your benefits partnering with us

Cameras and solutions made in Germany backed by a secure supply chain

Mature Quality Management System

Reliable product and supply chain to minimize the risk of penalties

Customizations with professional project management

Committed to your project and your product life cycle

Take your logistic imaging task to the next level!