Vision Guided Robotics with GigE Vision Mako and Prosilica GT cameras

Vision systems and robotics come together in all types of industrial applications. When a robot works without an associated system of vision, the work environment must be fixed and the robot must always go to a predetermined position which requires the use of highly precise location systems. Allied Vision's Distribution Partner Infaimon has developed a Vision guided robotic systems (VGR) that enable the position of any object in the space to be determined with extreme precision, using Allied Vision's Mako and Prosilica GT GigE Vision cameras.

The challenge

Recognition and location of randomly stacked objects

Vision systems and robotics come together in all types of industrial applications. This has led to an increase in the popularity of systems known as VGR (Vision Guided Robotics). When a robot works without an associated system of vision, the work environment must be fixed and the robot must always go to a predetermined position. This requires the use of highly precise location systems for the objects to be handled so that the robot moves exactly to where it is required to go.

In robotics and vision systems, picking refers to the combined process of identifying an object using a vision system, the determination of its position in the space and its subsequent picking and transfer to the destination point using a robotized system. Out of all picking applications, the best-known is probably the so-called “pick and place”. Normally, this involves the determination of the location of an object on a plane and its subsequent picking. These applications often aim to determine the location of an object on a conveyor belt.

The solution

Bin picking system based on stereo vision

Infaimon has developed a solution that does more than identify objects placed on a plane conveyor belt. It also permits the selection and extraction of parts stacked randomly in a bin. The bin picking system is based on stereo vision with two high resolution cameras implemented into the head piece of the robot. Two synchronized images enable the creation of a very precise, three dimensional map of all the objects in order to localize the best candidate for picking with great accuracy.

Two of Allied Vision’s GigE Vision camera models were selected as the two “artificial eyes” delivering the stereo vision image, just as human eyes would do. Depending on the special requirements of the application, either the small and low-cost Mako G-125 or the enhanced Prosilica GT1290 is applied. To ensure the accurate functioning of a robotic system, it is crucial to use the minimum amount of cables, so the robot arm won’t be too restricted. The selected GigE Vision cameras enable a power supply by “Power over Ethernet” (PoE) allowing both power and data transfer with one single cable.

The benefits

No time lost

The two Mako G or Prosilica GT cameras placed in the head piece, next to the robot arm, deliver a 3D image of the identified objects. However, this is not the only function of the cameras. While the robot is moving in a pre-defined trajectory within the 3D space, hundreds of images are taken creating a three-dimensional image of the environment. Views from different positions make hidden objects or zones visible, as the system generates a detailed map of the whole environment.

Having two cameras working simultaneously has various advantages. Using stereovision, production processes can become faster and more flexible. Objects don’t have to be stacked accurately and consistently, but can be filled randomly into a bin. No time is lost for sorting and aligning them before they are integrated into the products. Even highly complex structured parts can easily be identified. With other technologies, it is difficult to recognize these type of parts in a pile. The use of a stereo head helps to make safe and fast identification possible.

The camera: Mako G-125 or Prosilica GT1290

Synchronized images, from small to advanced

The Mako G-125 is an ultra-compact (29 x 29 mm) industrial GigE camera with Sony's ICX445 CCD sensor and various mounting options. Mako cameras are so small and light that they can easily be integrated into the robot’s head which further simplifies the usability of the system. For real stereo vision, the pair of cameras must capture and transmit synchronized images. Having various input and output options, the camera can easily be connected to an external computer sending a precise trigger.

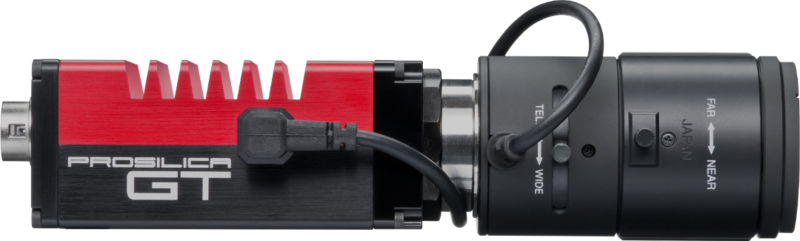

For advanced applications requiring perfectly synchronized images at faster read out times, the bin picking system can also be equipped with Allied Vision’s high-performance, 1.2 Megapixel GigE Vision Prosilica GT1290 camera. This camera includes Precision Time Protocol (PTP) which ensures the synchronization of the cameras within 2 microseconds across an Ethernet network.

Highlights at a glance

- Using stereovision, production processes can become faster and more flexible.

- No time is lost for sorting and aligning the objects before they are picked up.

- The cost for the hardware is very competitive in comparison to other 3D systems based on laser triangulation, pattern projection and time of flight.