Perfect interaction between the camera and AI

It’s what’s inside that counts

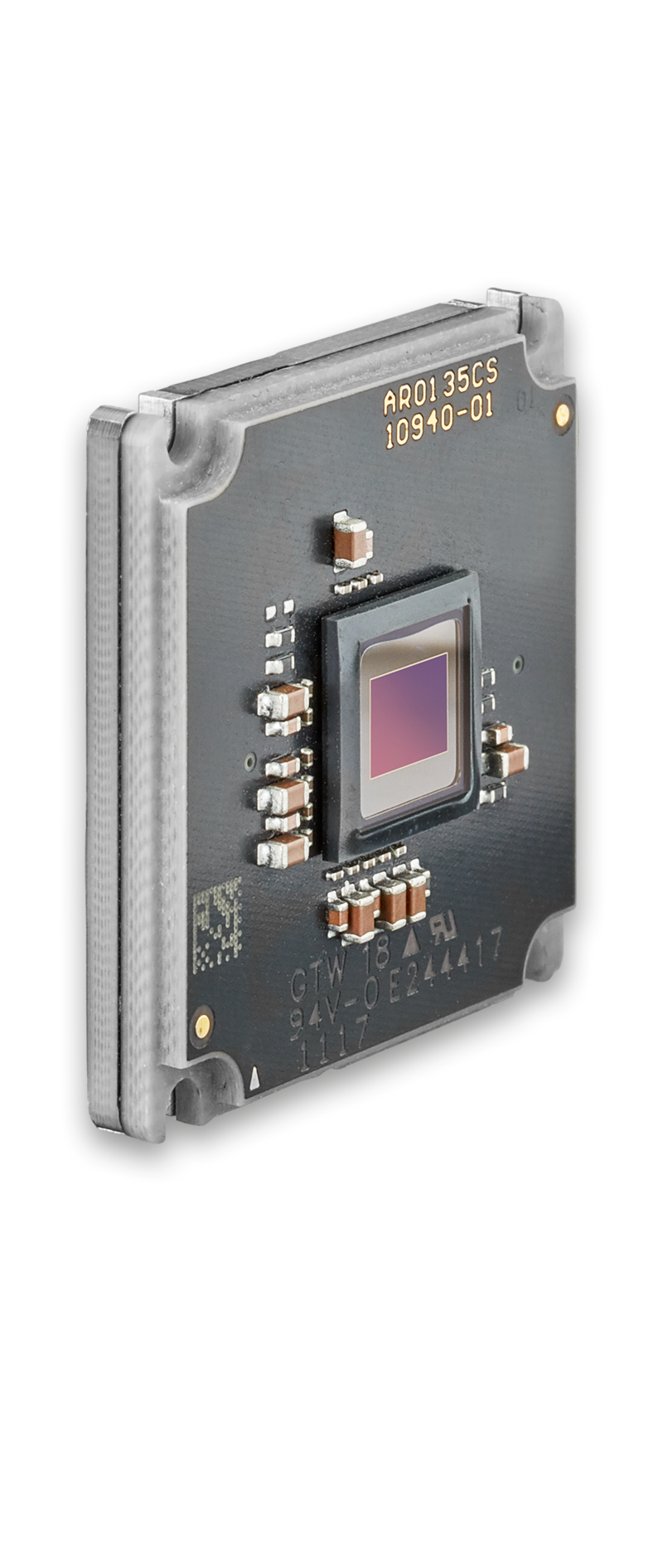

The image sensor: the centerpiece of the camera

Not all pictures are created equal! A wide variety of factors play a part here. You need to assess exactly what the camera or sensor should do for you and how these requirements will be implemented in economic terms. The following aspects should be considered:

Costs

- Image sensors are only mass-produced by a few manufacturers (e.g. Sony, OnSemi and LG). This makes sensors for industrial applications more expensive generally than for consumer products (such as smartphones), because the quantities are smaller. You should also expect higher costs for obtaining the best hardware for your application.

Features

- The price of a camera or image sensor can vary widely depending on its features.

Spectral sensitivity

- Depending on the sensor model, different light wavelength ranges are covered. This range can also be narrowed if necessary with the use of optical filters. Which wavelength do you need?

Clever combination

Smart solutions with embedded vision and artificial intelligence (AI)

Looking for something a bit more flexible? Embedded vision cameras are the first choice for special applications. They offer a high degree of customization and can be adapted optimally to the use of AI algorithms.

- Embedded vision is characterized by low energy consumption and little space – such as in a drone for aerial scanning. This opens up a whole new array of application fields.

- Sensor modules are more cost-effective compared to full cameras, but only offer basic features and require extra effort to develop in integration. This is worthwhile for high quantities and simple applications, such as in the retail sector.

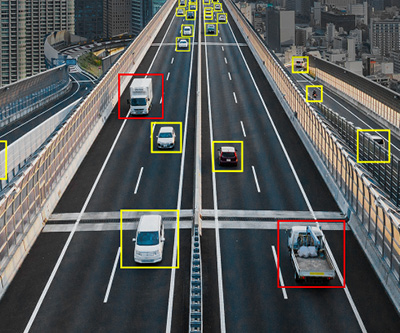

- AI on board – this makes a lot of sense for high quantities and low costs, such as in traffic and automotive applications. It allows a high level of compatibility, but limits the range of applications.

Also take advantage of our personal consulting for startups!